Introduction

This application note guides in selecting a battery backup for the DS36xx family of secure supervisors. These guidelines follow the same fundamental rules that have historically been applied to any Maxim nonvolatile memory product. Due to the special circuit-monitoring demands of a secure supervisor, additional care is necessary to assure that the battery provides years of useful field life in the final system.Determine the Acceptable Battery Voltage

The first step is to determine the maximum DC operating voltage allowed on the VBAT input. This value will be a basic DS36xx specification found in the respective product data sheet. This voltage limit should not be confused with the devices' Absolute Maximum Rating, which is the elevated bias at which physical damage to the component can occur. This DC operating voltage should also be compatible with any downstream components that will be supported by the secure supervisor.Using the allowable battery voltage range for the product, several choices of battery chemistry are available (see Table 1). System environmental requirements may influence the selection of chemistry.

Table 1. Lithium Battery Characteristics

| Battery Type | Chemistry | Nominal Voltage (V) | Maximum Voltage (V) | Nominal Discharge Current (μA) | Temperature Range (°C) |

| BR Lithium Coin (primary) | Polycarbon monofluoride (CF)n | 3.0 | 3.45 | 30 | -30 to +80 |

| BRA Lithium Coin (primary) | Polycarbon monofluoride (CF)n | 3.0 | 3.45 | 30 | -40 to +125 |

| CR Lithium Coin (primary) | Manganese dioxide (MnO2) | 3.0 | 3.35 | 100 to 200 | -30 to +60 |

| VL Lithium Coin (secondary) | Vanadium pentoxide (V2O5) | 3.0 | 3.60(1) | 10 to 200 | -20 to +60 |

| ML Lithium Coin (secondary) | Manganese lithium | 2.5 | 3.10 | 5 to 100 | -20 to +60 |

| Thionyl Chloride Lithium (secondary) | Lithium-thionyl chloride (Li-SOCl2) | 3.6 | 3.67 | 1mA to 5mA | -55 to +85 |

| Lithium-Ion (secondary) | Li+ | 3.6 | 4.201 | 1500mA to 2500mA | 0 to +45 |

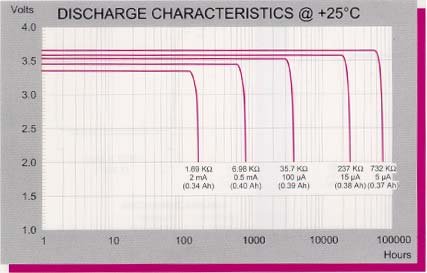

Given three options for primary (nonrechargeable) coin cells, the required system operating temperature can weigh heavily in your final choice. The BR chemistry has better high-temperature current delivery capabilities than an equivalent-sized CR chemistry cell.2 Alternatively, if the system is operating at temperatures below +10°C, the current delivery characteristics of a CR chemistry cell are generally superior to the BR chemistry. In any case, a primary cell is a one-shot energy source and must eventually be replaced. A careful comparison of the battery manufacturer's discharge characteristic plots may offer better insight into the strengths and weaknesses of that chemistry than this abbreviated article can do.

In the list of secondary (rechargeable) batteries, each type has some advantage and disadvantage to evaluate. The nominal voltage of a thionyl chloride or lithium-ion battery usually exceeds the allowable range for the DS36xx products, so that voltage must be reduced through use of a regulator or diode drop. The same voltage issue can impact selection of a VL coin cell, unless the charging voltage is controlled. The nominal voltage of the ML coin cell may be too low for extended-duration battery backup. The temperature range of the lithium-ion battery is quite limited, although the charge capacity is superior to almost any other option.

There are other influences in your battery selection process (i.e., physical size or mass, cost, transport and/or disposal restrictions) that can also preference or eliminate specific battery chemistries from consideration.

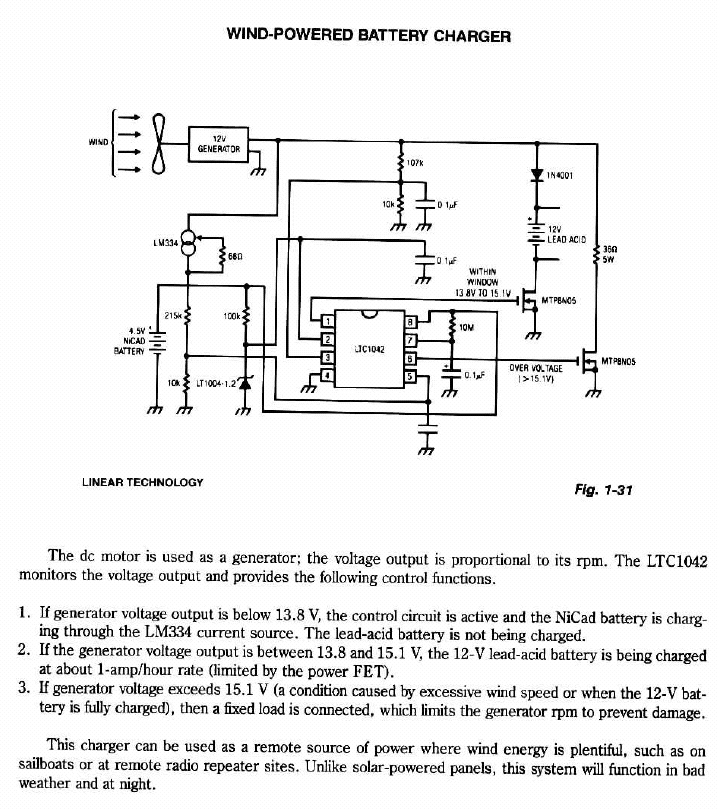

For this discussion, we selected a BRA-chemistry (polycarbon monofluoride) primary lithium coin cell, due to the low-current demands and wide operating temperature range for the system. The maximum (new cell) voltage of a BRA cell is +3.45V,2 which falls within the required range of acceptable battery voltages for the component used in our typical circuit (Figure 1).

Determine the Battery Capacity Requirement

Using a simplified intrusion-monitoring application, Figure 1 will be referenced for total battery current consumption. The cabinet security interlocks are represented as switches S1 to S4.From the system schematic, the total battery current must be mathematically derived from the summation of all currents associated with the DS36xx and support circuitry. These current calculations should include any digital and/or analog input leakage currents (IL); logic output drive currents (IOH); any pass-through currents required to operate external memory or support circuitry (ICCO); and the battery current consumed solely by the DS36xx component (IBAT).

Figure 1. Typical operating circuit for a DS36xx secure supervisor.

During battery backup operations, external power and I/O (VCCI, SDA, and SCL) are all at 0V. In the Figure 1 schematic, the total current load on VCCO (ICCO) is the potential input leakage of the four "INx" input pins, plus the potential output pulldown current (IRPD), should the active-low Tamper output activate.

Current Load Calculation IBAT 6.5μA (From product specification; maximum value with no load) X1/X2 Part of IBAT ? IN1 0.1μA (max) (From product specification; input leakage) IN2 0.1μA (max) (From product specification - input leakage) Active-low IN3 0.1μA (max) (From product specification - input leakage) Active-low IN4 0.1μA (max) (From product specification - input leakage) Active-low Tamper 3.3μA (Active-low Tamper output current with 1MΩ pullup resistor) --------------------------------------- Total 10.2μA ?

Determine the Useful Field Lifetime Expectancy

With the current load calculated, the remaining variable to assess is the desired system lifetime while operating on the battery. For this discussion, the intent is to create a product with a 10-year battery field lifetime.Battery Capacity Calculation

10 years = 87,660 hours (24hrs × 365.25days/yr × 10yrs)

10.2μA continuous current load for 87,660hrs = 894mAh

Select a Specific Battery

After previously selecting the BRA chemistry based on cell voltage and operational temperature range, the task of final battery selection is reduced to picking an item that meets or exceeds the capacity demands from the vendor's list of available cells (Table 2).Table 2. BRA Chemistry Product Selection

| Battery Model | Nominal Voltage (V) | Nominal Capacity (mAh) | Cell Diameter (mm) | Cell Height (mm) | Weight (g) |

| BR1225A | 3 | 48 | 12.5 | 2.5 | 0.8 |

| BR1632A | 3 | 120 | 16.0 | 3.2 | 1.5 |

| BR2330A | 3 | 255 | 23.0 | 3.0 | 3.2 |

| BR2450A | 3 | 550 | 24.5 | 5.0 | 5.0 |

| BR2477A | 3 | 1000 | 24.5 | 7.7 | 8.0 |

From the manufacturer's product table, the BR2477A cell is rated for 1000mAh (1Ah), and should provide ~11.2 years of battery life in the Figure 1 circuit.

1000mAh/10.2μA = 98,039 hours (11.18 years)If the required battery capacity is greater than any of the available cells, the designer must evaluate the trade-offs among: 1) using another battery chemistry; 2) reducing the load current; 3) reducing the expected field life of the battery; or 4) executing a combination of those options. Load-current reductions can possibly be achieved by reducing the output currents on any open-drain devices (i.e., selecting higher resistor values), or in some DS36xx products, by implementing power-management options.

Conclusion

This article reviewed several factors that influence battery selection and provided the preferred choices of battery chemistry. Some of the first-order analysis necessary to properly select a battery for use with a secure supervisor was explained. In some of the process, we demonstrated the steps necessary to mate an integrated circuit with the battery best suited to support this security-specific application for many years.Notes

- Charge is voltage dependant.

- Not specified in battery data sheet. May require additional battery characterization.

電子發(fā)燒友App

電子發(fā)燒友App

評(píng)論