SPI驅動ST7789V1.47寸LCD

R128 平臺提供了 SPI DBI 的 SPI TFT 接口,具有如下特點:

- Supports DBI Type C 3 Line/4 Line Interface Mode

- Supports 2 Data Lane Interface Mode

- Supports data source from CPU or DMA

- Supports RGB111/444/565/666/888 video format

- Maximum resolution of RGB666 240 x 320@30Hz with single data lane

- Maximum resolution of RGB888 240 x 320@60Hz or 320 x 480@30Hz with dual data lane

- Supports tearing effect

- Supports software flexible control video frame rate

同時,提供了 SPILCD 驅動框架以供 SPI 屏幕使用。

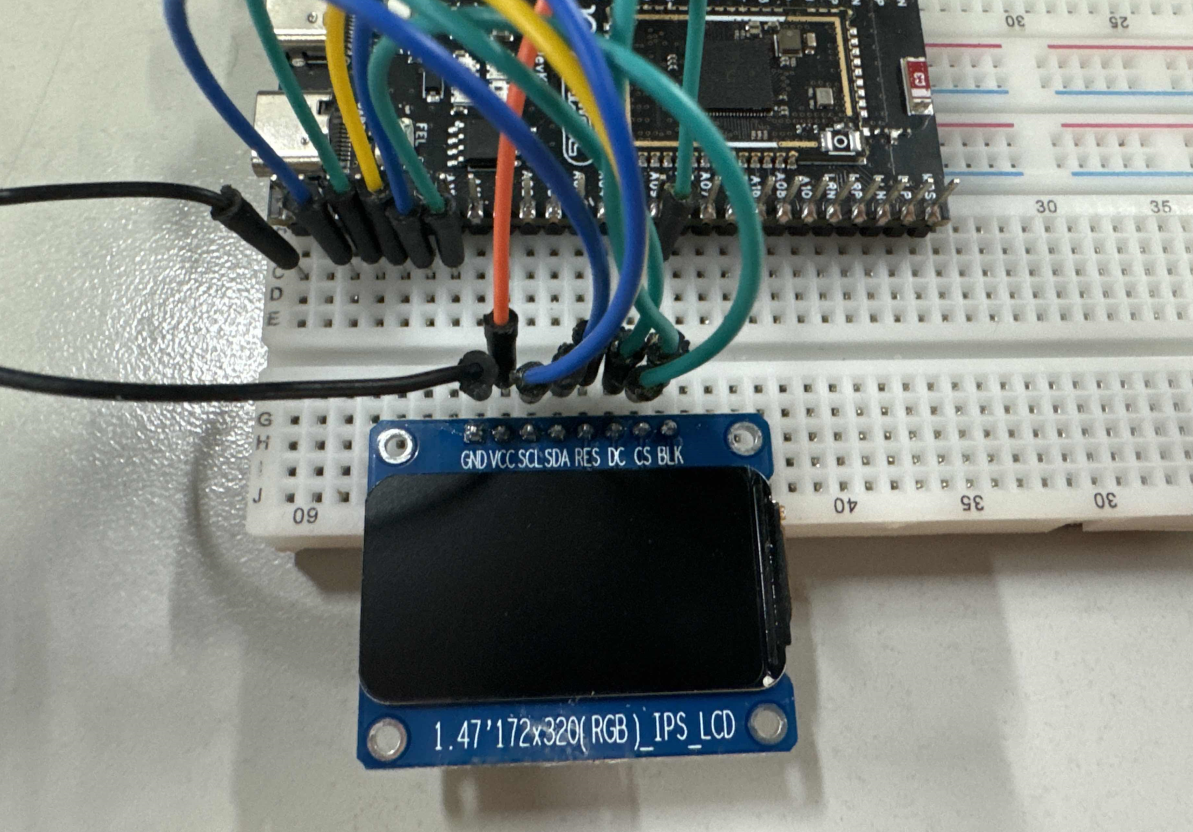

此次適配的SPI屏為 ZJY147S0800TG01,使用的是 SPI 進行驅動。

引腳配置如下:

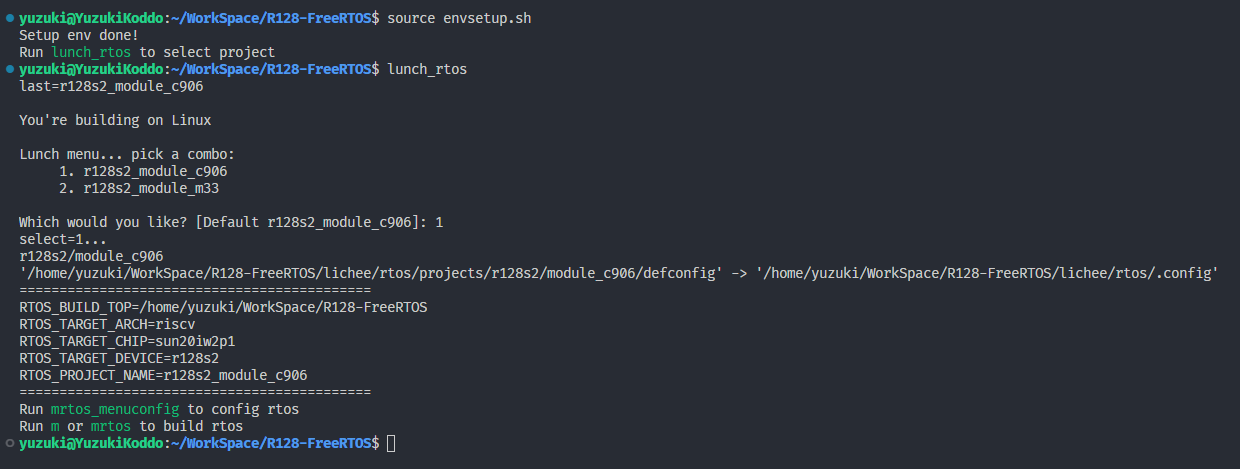

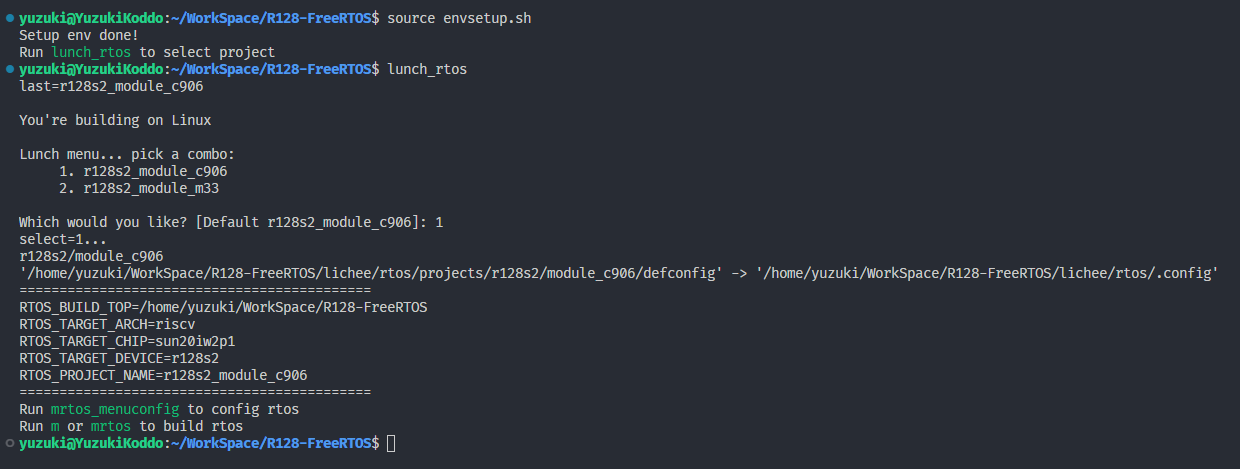

載入方案

我們使用的開發板是 R128-Devkit,需要開發 C906 核心的應用程序,所以載入方案選擇 r128s2_module_c906

$ source envsetup.sh

$ lunch_rtos 1

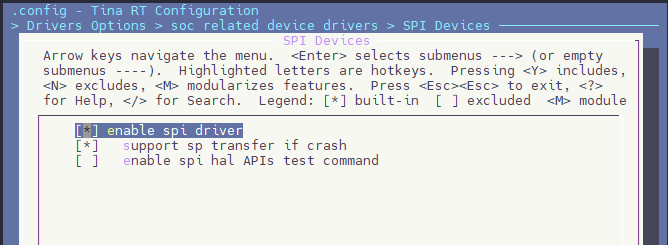

設置 SPI 驅動

屏幕使用的是SPI驅動,所以需要勾選SPI驅動,運行 mrtos_menuconfig 進入配置頁面。前往下列地址找到 SPI Devices

Drivers Options --- >

soc related device drivers --- >

SPI Devices --- >

-*- enable spi driver

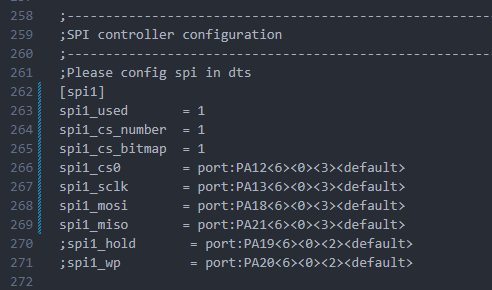

配置 SPI 引腳

打開你喜歡的編輯器,修改文件:board/r128s2/module/configs/sys_config.fex,在這里我們不需要用到 SPI HOLD與SPI WP引腳,注釋掉即可。

;----------------------------------------------------------------------------------

;SPI controller configuration

;----------------------------------------------------------------------------------

;Please config spi in dts

[spi1]

spi1_used = 1

spi1_cs_number = 1

spi1_cs_bitmap = 1

spi1_cs0 = port:PA12< 6 >< 0 >< 3 >< default >

spi1_sclk = port:PA13< 6 >< 0 >< 3 >< default >

spi1_mosi = port:PA18< 6 >< 0 >< 3 >< default >

spi1_miso = port:PA21< 6 >< 0 >< 3 >< default >

;spi1_hold = port:PA19< 6 >< 0 >< 2 >< default >

;spi1_wp = port:PA20< 6 >< 0 >< 2 >< default >

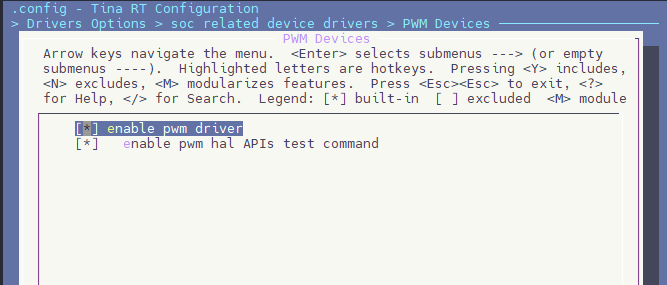

設置 PWM 驅動

屏幕背光使用的是PWM驅動,所以需要勾選PWM驅動,運行 mrtos_menuconfig 進入配置頁面。前往下列地址找到 PWM Devices

Drivers Options --- >

soc related device drivers --- >

PWM Devices --- >

-*- enable pwm driver

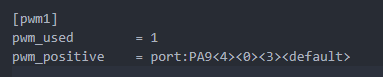

配置 PWM 引腳

打開你喜歡的編輯器,修改文件:board/r128s2/module/configs/sys_config.fex,增加 PWM1 節點

[pwm1]

pwm_used = 1

pwm_positive = port:PA9< 4 >< 0 >< 3 >< default >

設置 SPI LCD 驅動

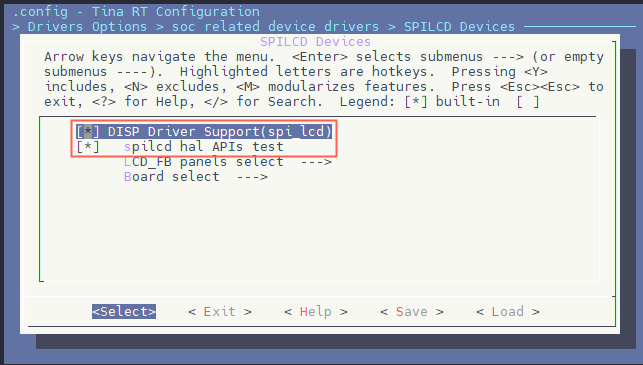

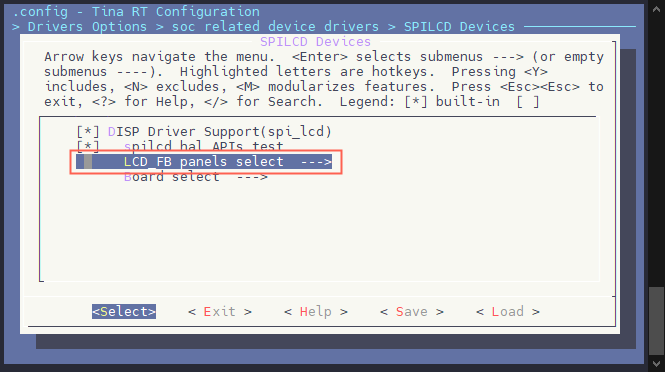

SPI LCD 由專門的驅動管理。運行 mrtos_menuconfig 進入配置頁面。前往下列地址找到 SPILCD Devices ,注意同時勾選 spilcd hal APIs test 方便測試使用。

Drivers Options --- >

soc related device drivers --- >

[*] DISP Driver Support(spi_lcd)

[*] spilcd hal APIs test

編寫 SPI LCD 顯示屏驅動

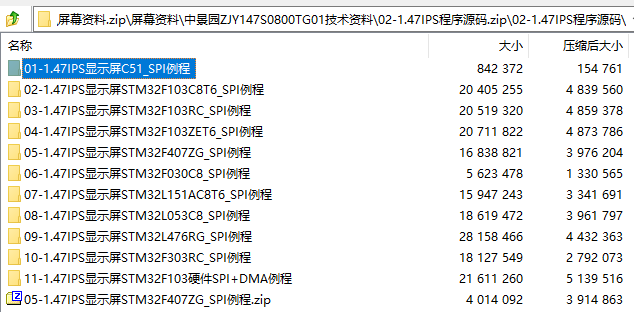

獲取屏幕初始化序列

首先詢問屏廠提供驅動源碼

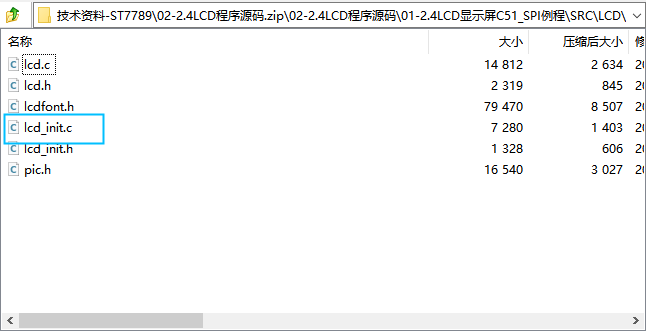

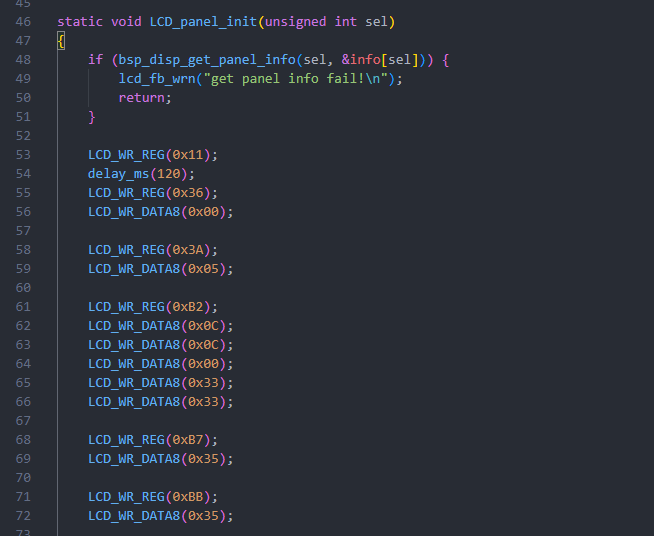

找到 LCD 的初始化序列代碼

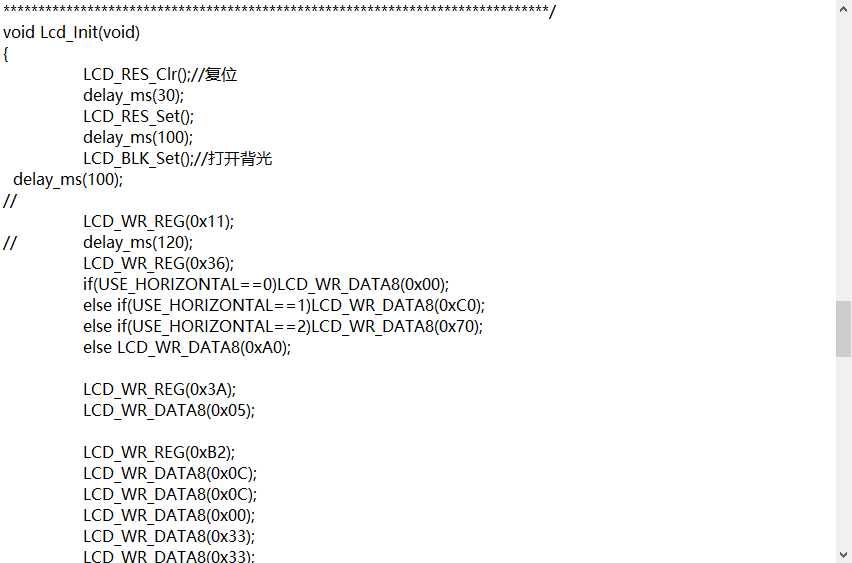

找到屏幕初始化的源碼

整理后的初始化代碼如下:

LCD_WR_REG(0x11);

delay_ms(120);

LCD_WR_REG(0x36);

LCD_WR_DATA8(0x00);

LCD_WR_REG(0x3A);

LCD_WR_DATA8(0x05);

LCD_WR_REG(0xB2);

LCD_WR_DATA8(0x0C);

LCD_WR_DATA8(0x0C);

LCD_WR_DATA8(0x00);

LCD_WR_DATA8(0x33);

LCD_WR_DATA8(0x33);

LCD_WR_REG(0xB7);

LCD_WR_DATA8(0x35);

LCD_WR_REG(0xBB);

LCD_WR_DATA8(0x35);

LCD_WR_REG(0xC0);

LCD_WR_DATA8(0x2C);

LCD_WR_REG(0xC2);

LCD_WR_DATA8(0x01);

LCD_WR_REG(0xC3);

LCD_WR_DATA8(0x13);

LCD_WR_REG(0xC4);

LCD_WR_DATA8(0x20);

LCD_WR_REG(0xC6);

LCD_WR_DATA8(0x0F);

LCD_WR_REG(0xD0);

LCD_WR_DATA8(0xA4);

LCD_WR_DATA8(0xA1);

LCD_WR_REG(0xD6);

LCD_WR_DATA8(0xA1);

LCD_WR_REG(0xE0);

LCD_WR_DATA8(0xF0);

LCD_WR_DATA8(0x00);

LCD_WR_DATA8(0x04);

LCD_WR_DATA8(0x04);

LCD_WR_DATA8(0x04);

LCD_WR_DATA8(0x05);

LCD_WR_DATA8(0x29);

LCD_WR_DATA8(0x33);

LCD_WR_DATA8(0x3E);

LCD_WR_DATA8(0x38);

LCD_WR_DATA8(0x12);

LCD_WR_DATA8(0x12);

LCD_WR_DATA8(0x28);

LCD_WR_DATA8(0x30);

LCD_WR_REG(0xE1);

LCD_WR_DATA8(0xF0);

LCD_WR_DATA8(0x07);

LCD_WR_DATA8(0x0A);

LCD_WR_DATA8(0x0D);

LCD_WR_DATA8(0x0B);

LCD_WR_DATA8(0x07);

LCD_WR_DATA8(0x28);

LCD_WR_DATA8(0x33);

LCD_WR_DATA8(0x3E);

LCD_WR_DATA8(0x36);

LCD_WR_DATA8(0x14);

LCD_WR_DATA8(0x14);

LCD_WR_DATA8(0x29);

LCD_WR_DATA8(0x32);

LCD_WR_REG(0x21);

LCD_WR_REG(0x11);

delay_ms(120);

LCD_WR_REG(0x29);

用現成驅動改寫 SPI LCD 驅動

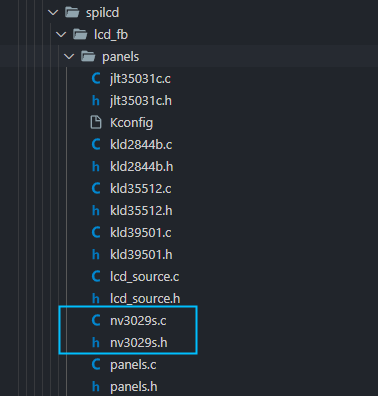

選擇一個現成的 SPI LCD 改寫即可,這里選擇 nv3029s.c 驅動來修改

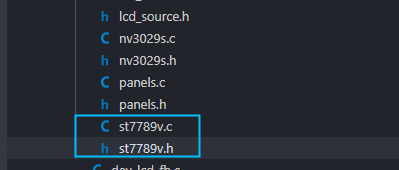

復制這兩個驅動,重命名為 st7789v.c

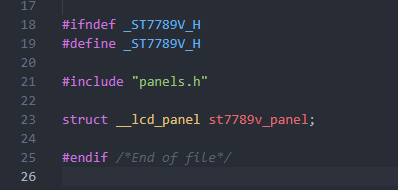

先編輯 st7789v.h 將 nv3029s 改成 st7789v

#ifndef _ST7789V_H

#define _ST7789V_H

#include "panels.h"

struct __lcd_panel st7789v_panel;

#endif /*End of file*/

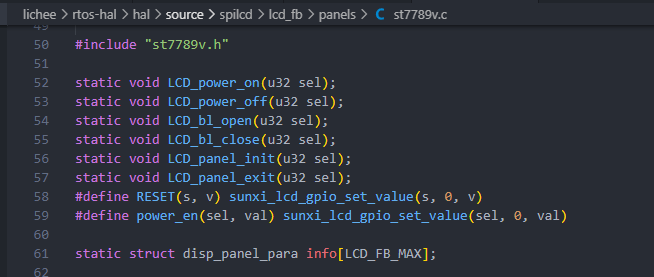

編輯 st7789v.c 將 nv3029s 改成 st7789v

編寫初始化序列

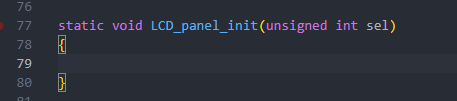

先刪除 static void LCD_panel_init(unsigned int sel) 中的初始化函數。

然后將屏廠提供的初始化序列復制進來

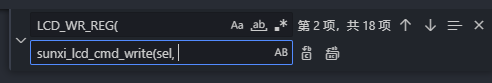

然后按照 spi_lcd 框架的接口改寫驅動接口,具體接口如下

屏廠函數

SPILCD框架接口

LCD_WR_REG

sunxi_lcd_cmd_write

LCD_WR_DATA8

sunxi_lcd_para_write

delay_ms

sunxi_lcd_delay_ms

可以直接進行替換

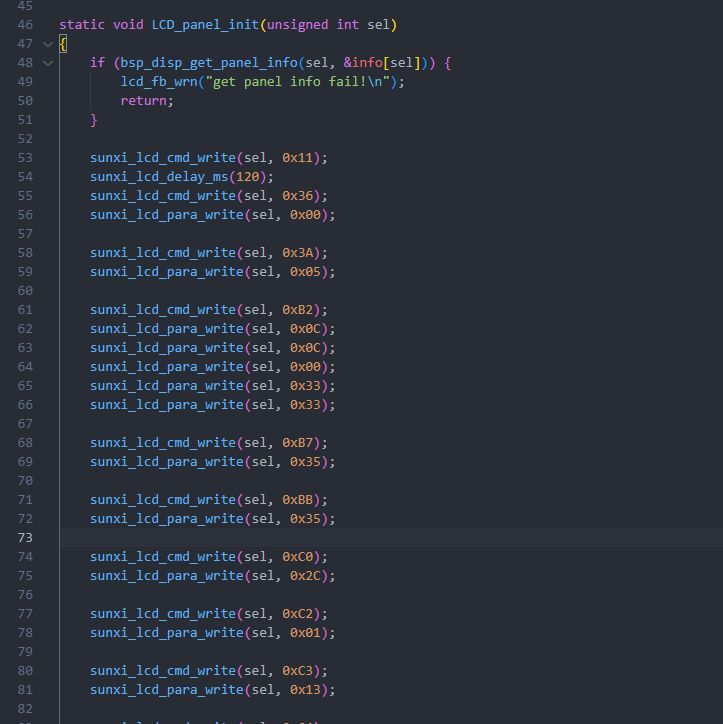

完成后如下

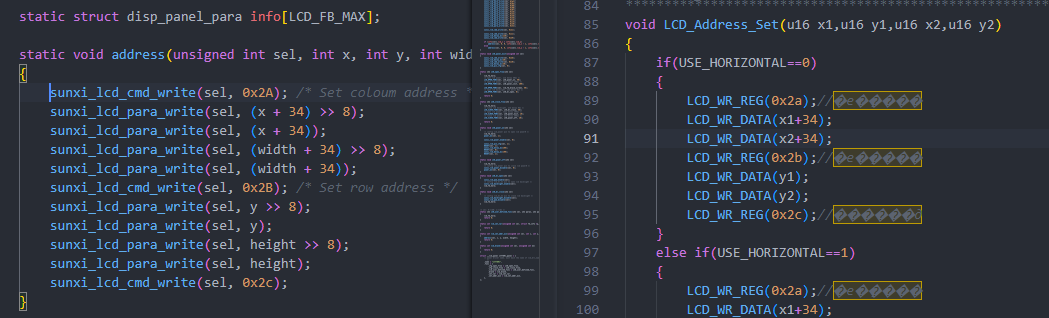

然后對照屏廠提供的驅動修改 address 函數

做如下修改

static void address(unsigned int sel, int x, int y, int width, int height)

{

sunxi_lcd_cmd_write(sel, 0x2A); /* Set coloum address */

sunxi_lcd_para_write(sel, (x + 34) > > 8);

sunxi_lcd_para_write(sel, (x + 34));

sunxi_lcd_para_write(sel, (width + 34) > > 8);

sunxi_lcd_para_write(sel, (width + 34));

sunxi_lcd_cmd_write(sel, 0x2B); /* Set row address */

sunxi_lcd_para_write(sel, y > > 8);

sunxi_lcd_para_write(sel, y);

sunxi_lcd_para_write(sel, height > > 8);

sunxi_lcd_para_write(sel, height);

sunxi_lcd_cmd_write(sel, 0x2c);

}

完成驅動如下

#include "st7789v.h"

static void LCD_power_on(u32 sel);

static void LCD_power_off(u32 sel);

static void LCD_bl_open(u32 sel);

static void LCD_bl_close(u32 sel);

static void LCD_panel_init(u32 sel);

static void LCD_panel_exit(u32 sel);

#define RESET(s, v) sunxi_lcd_gpio_set_value(s, 0, v)

#define power_en(sel, val) sunxi_lcd_gpio_set_value(sel, 0, val)

static struct disp_panel_para info[LCD_FB_MAX];

static void address(unsigned int sel, int x, int y, int width, int height)

{

sunxi_lcd_cmd_write(sel, 0x2A); /* Set coloum address */

sunxi_lcd_para_write(sel, (x + 34) > > 8);

sunxi_lcd_para_write(sel, (x + 34));

sunxi_lcd_para_write(sel, (width + 34) > > 8);

sunxi_lcd_para_write(sel, (width + 34));

sunxi_lcd_cmd_write(sel, 0x2B); /* Set row address */

sunxi_lcd_para_write(sel, y > > 8);

sunxi_lcd_para_write(sel, y);

sunxi_lcd_para_write(sel, height > > 8);

sunxi_lcd_para_write(sel, height);

sunxi_lcd_cmd_write(sel, 0x2c);

}

static void LCD_panel_init(unsigned int sel)

{

if (bsp_disp_get_panel_info(sel, &info[sel])) {

lcd_fb_wrn("get panel info fail!n");

return;

}

sunxi_lcd_cmd_write(sel, 0x11);

sunxi_lcd_delay_ms(120);

sunxi_lcd_cmd_write(sel, 0x36);

sunxi_lcd_para_write(sel, 0x00);

sunxi_lcd_cmd_write(sel, 0x3A);

sunxi_lcd_para_write(sel, 0x05);

sunxi_lcd_cmd_write(sel, 0xB2);

sunxi_lcd_para_write(sel, 0x0C);

sunxi_lcd_para_write(sel, 0x0C);

sunxi_lcd_para_write(sel, 0x00);

sunxi_lcd_para_write(sel, 0x33);

sunxi_lcd_para_write(sel, 0x33);

sunxi_lcd_cmd_write(sel, 0xB7);

sunxi_lcd_para_write(sel, 0x35);

sunxi_lcd_cmd_write(sel, 0xBB);

sunxi_lcd_para_write(sel, 0x35);

sunxi_lcd_cmd_write(sel, 0xC0);

sunxi_lcd_para_write(sel, 0x2C);

sunxi_lcd_cmd_write(sel, 0xC2);

sunxi_lcd_para_write(sel, 0x01);

sunxi_lcd_cmd_write(sel, 0xC3);

sunxi_lcd_para_write(sel, 0x13);

sunxi_lcd_cmd_write(sel, 0xC4);

sunxi_lcd_para_write(sel, 0x20);

sunxi_lcd_cmd_write(sel, 0xC6);

sunxi_lcd_para_write(sel, 0x0F);

sunxi_lcd_cmd_write(sel, 0xD0);

sunxi_lcd_para_write(sel, 0xA4);

sunxi_lcd_para_write(sel, 0xA1);

sunxi_lcd_cmd_write(sel, 0xD6);

sunxi_lcd_para_write(sel, 0xA1);

sunxi_lcd_cmd_write(sel, 0xE0);

sunxi_lcd_para_write(sel, 0xF0);

sunxi_lcd_para_write(sel, 0x00);

sunxi_lcd_para_write(sel, 0x04);

sunxi_lcd_para_write(sel, 0x04);

sunxi_lcd_para_write(sel, 0x04);

sunxi_lcd_para_write(sel, 0x05);

sunxi_lcd_para_write(sel, 0x29);

sunxi_lcd_para_write(sel, 0x33);

sunxi_lcd_para_write(sel, 0x3E);

sunxi_lcd_para_write(sel, 0x38);

sunxi_lcd_para_write(sel, 0x12);

sunxi_lcd_para_write(sel, 0x12);

sunxi_lcd_para_write(sel, 0x28);

sunxi_lcd_para_write(sel, 0x30);

sunxi_lcd_cmd_write(sel, 0xE1);

sunxi_lcd_para_write(sel, 0xF0);

sunxi_lcd_para_write(sel, 0x07);

sunxi_lcd_para_write(sel, 0x0A);

sunxi_lcd_para_write(sel, 0x0D);

sunxi_lcd_para_write(sel, 0x0B);

sunxi_lcd_para_write(sel, 0x07);

sunxi_lcd_para_write(sel, 0x28);

sunxi_lcd_para_write(sel, 0x33);

sunxi_lcd_para_write(sel, 0x3E);

sunxi_lcd_para_write(sel, 0x36);

sunxi_lcd_para_write(sel, 0x14);

sunxi_lcd_para_write(sel, 0x14);

sunxi_lcd_para_write(sel, 0x29);

sunxi_lcd_para_write(sel, 0x32);

sunxi_lcd_cmd_write(sel, 0x21);

sunxi_lcd_cmd_write(sel, 0x11);

sunxi_lcd_delay_ms(120);

sunxi_lcd_cmd_write(sel, 0x29);

if (info[sel].lcd_x < info[sel].lcd_y)

address(sel, 0, 0, info[sel].lcd_x - 1, info[sel].lcd_y - 1);

else

address(sel, 0, 0, info[sel].lcd_y - 1, info[sel].lcd_x - 1);

}

static void LCD_panel_exit(unsigned int sel)

{

sunxi_lcd_cmd_write(sel, 0x28);

sunxi_lcd_delay_ms(20);

sunxi_lcd_cmd_write(sel, 0x10);

sunxi_lcd_delay_ms(20);

sunxi_lcd_pin_cfg(sel, 0);

}

static s32 LCD_open_flow(u32 sel)

{

lcd_fb_here;

/* open lcd power, and delay 50ms */

LCD_OPEN_FUNC(sel, LCD_power_on, 50);

/* open lcd power, than delay 200ms */

LCD_OPEN_FUNC(sel, LCD_panel_init, 200);

LCD_OPEN_FUNC(sel, lcd_fb_black_screen, 50);

/* open lcd backlight, and delay 0ms */

LCD_OPEN_FUNC(sel, LCD_bl_open, 0);

return 0;

}

static s32 LCD_close_flow(u32 sel)

{

lcd_fb_here;

/* close lcd backlight, and delay 0ms */

LCD_CLOSE_FUNC(sel, LCD_bl_close, 50);

/* open lcd power, than delay 200ms */

LCD_CLOSE_FUNC(sel, LCD_panel_exit, 10);

/* close lcd power, and delay 500ms */

LCD_CLOSE_FUNC(sel, LCD_power_off, 10);

return 0;

}

static void LCD_power_on(u32 sel)

{

/* config lcd_power pin to open lcd power0 */

lcd_fb_here;

power_en(sel, 1);

sunxi_lcd_power_enable(sel, 0);

sunxi_lcd_pin_cfg(sel, 1);

RESET(sel, 1);

sunxi_lcd_delay_ms(100);

RESET(sel, 0);

sunxi_lcd_delay_ms(100);

RESET(sel, 1);

}

static void LCD_power_off(u32 sel)

{

lcd_fb_here;

/* config lcd_power pin to close lcd power0 */

sunxi_lcd_power_disable(sel, 0);

power_en(sel, 0);

}

static void LCD_bl_open(u32 sel)

{

sunxi_lcd_pwm_enable(sel);

/* config lcd_bl_en pin to open lcd backlight */

sunxi_lcd_backlight_enable(sel);

lcd_fb_here;

}

static void LCD_bl_close(u32 sel)

{

/* config lcd_bl_en pin to close lcd backlight */

sunxi_lcd_backlight_disable(sel);

sunxi_lcd_pwm_disable(sel);

lcd_fb_here;

}

/* sel: 0:lcd0; 1:lcd1 */

static s32 LCD_user_defined_func(u32 sel, u32 para1, u32 para2, u32 para3)

{

lcd_fb_here;

return 0;

}

static int lcd_set_var(unsigned int sel, struct fb_info *p_info)

{

return 0;

}

static int lcd_set_addr_win(unsigned int sel, int x, int y, int width, int height)

{

address(sel, x, y, width, height);

return 0;

}

static int lcd_blank(unsigned int sel, unsigned int en)

{

return 0;

}

struct __lcd_panel st7789v_panel = {

/* panel driver name, must mach the name of lcd_drv_name in sys_config.fex

*/

.name = "st7789v",

.func = {

.cfg_open_flow = LCD_open_flow,

.cfg_close_flow = LCD_close_flow,

.lcd_user_defined_func = LCD_user_defined_func,

.blank = lcd_blank,

.set_var = lcd_set_var,

.set_addr_win = lcd_set_addr_win,

},

};

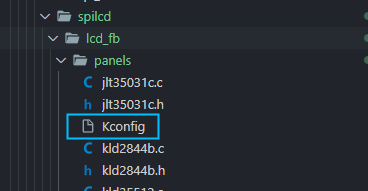

對接驅動框架

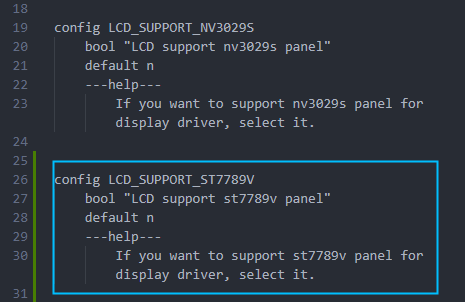

完成了屏幕驅動的編寫,接下來需要對接到 SPILCD 驅動框架。首先編輯 Kconfig

增加 st7789v 的配置

config LCD_SUPPORT_ST7789V

bool "LCD support st7789v panel"

default n

---help---

If you want to support st7789v panel for display driver, select it.

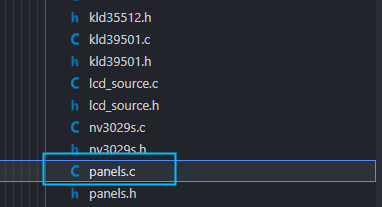

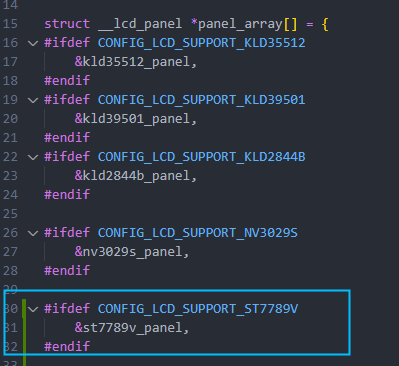

然后編輯 panels.c 在 panel_array 里增加 st7789 驅動的引用

如下圖

#ifdef CONFIG_LCD_SUPPORT_ST7789V

&st7789v_panel,

#endif

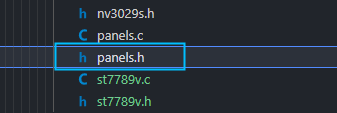

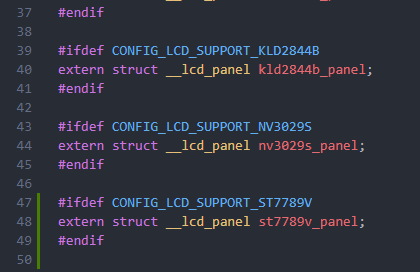

之后編輯 panels.h 同樣增加引用

如下圖

#ifdef CONFIG_LCD_SUPPORT_ST7789V

extern struct __lcd_panel st7789v_panel;

#endif

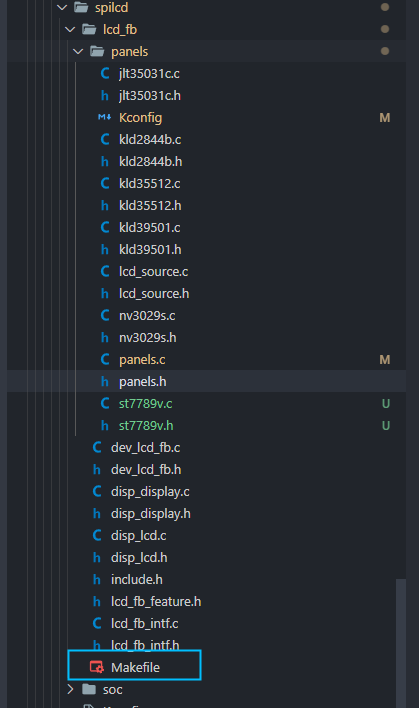

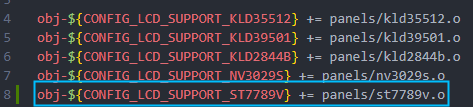

最后編輯外層的 Makefile 增加編譯選項

如下所示

obj-${CONFIG_LCD_SUPPORT_ST7789V} += panels/st7789v.o

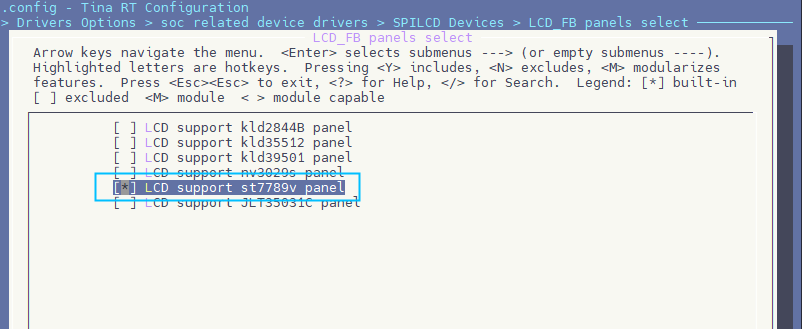

選擇 ST7789V 驅動

在 SPILCD 驅動選擇界面可以看到 LCD_FB panels select 選擇 SPI 屏幕的驅動

進入 LCD_FB panels select 選項

選擇并勾選 [*] LCD support st7789v panel

配置 SPI LCD 引腳

打開你喜歡的編輯器,修改文件:board/r128s2/module/configs/sys_config.fex

[lcd_fb0]

lcd_used = 1

lcd_model_name = "spilcd"

lcd_driver_name = "st7789v"

lcd_x = 172

lcd_y = 320

lcd_width = 17

lcd_height = 32

lcd_data_speed = 50

lcd_pwm_used = 1

lcd_pwm_ch = 1

lcd_pwm_freq = 5000

lcd_pwm_pol = 0

lcd_if = 0

lcd_pixel_fmt = 11

lcd_dbi_fmt = 2

lcd_dbi_clk_mode = 1

lcd_dbi_te = 1

fb_buffer_num = 2

lcd_dbi_if = 4

lcd_rgb_order = 0

lcd_fps = 60

lcd_spi_bus_num = 1

lcd_frm = 2

lcd_gamma_en = 1

lcd_backlight = 100

lcd_power_num = 0

lcd_gpio_regu_num = 0

lcd_bl_percent_num = 0

lcd_spi_dc_pin = port:PA19< 1 >< 0 >< 3 >< 0 >

;RESET Pin

lcd_gpio_0 = port:PA20< 1 >< 0 >< 2 >< 0 >

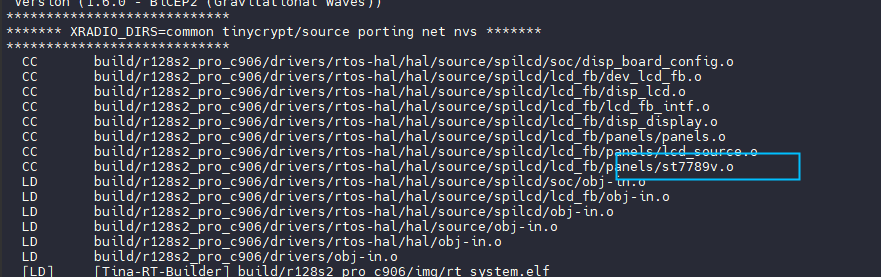

編譯打包

運行命令 mp 編譯打包,可以看到編譯了 st7789v.o

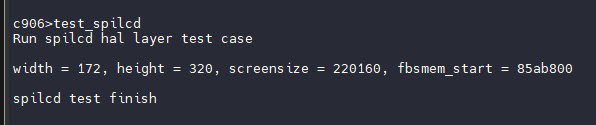

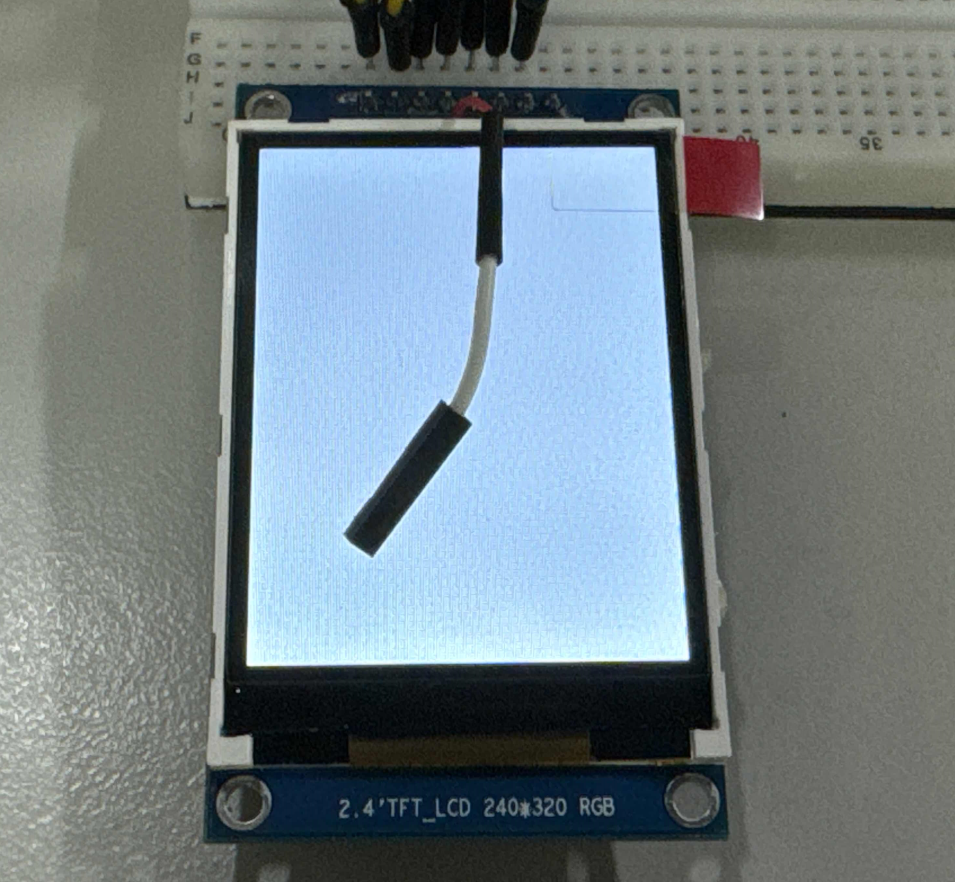

測試

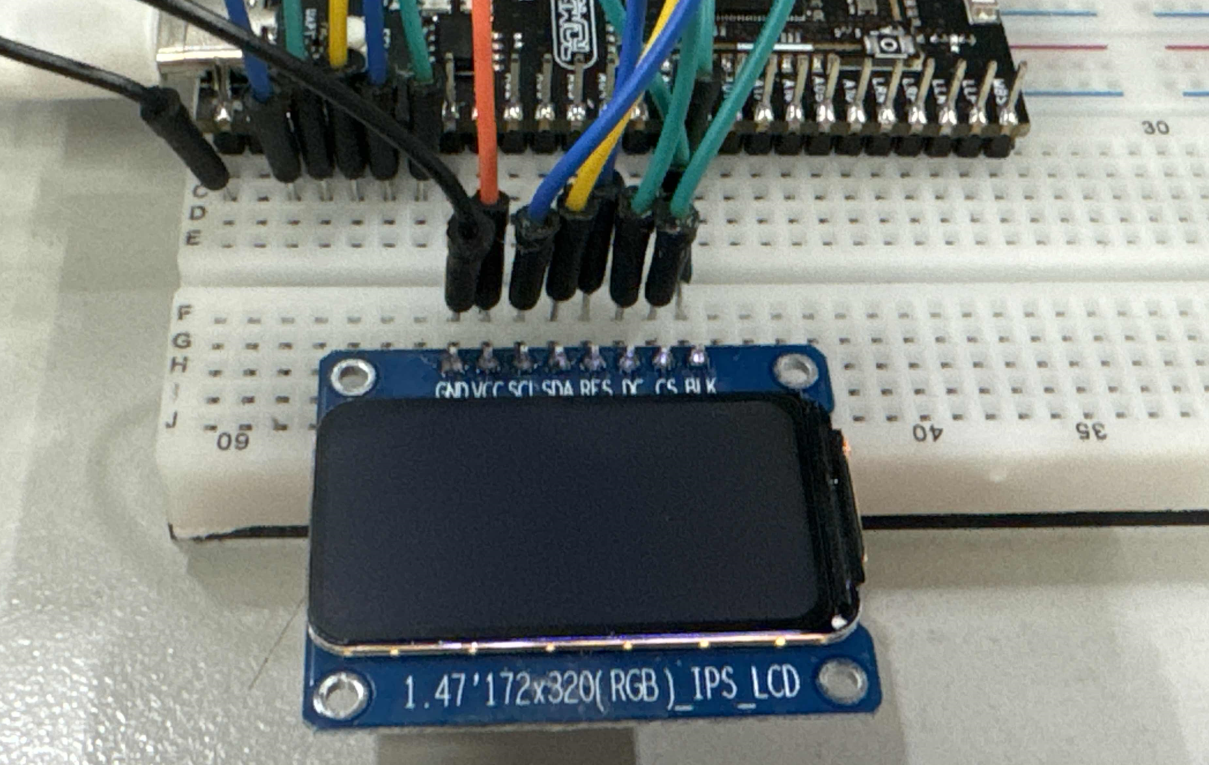

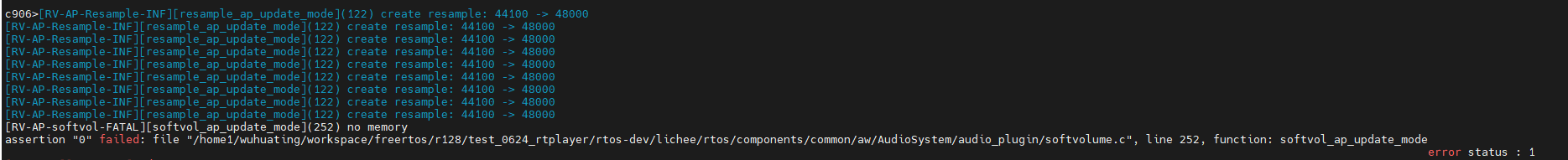

燒錄啟動之后,屏幕背光啟動,但是屏幕全黑。

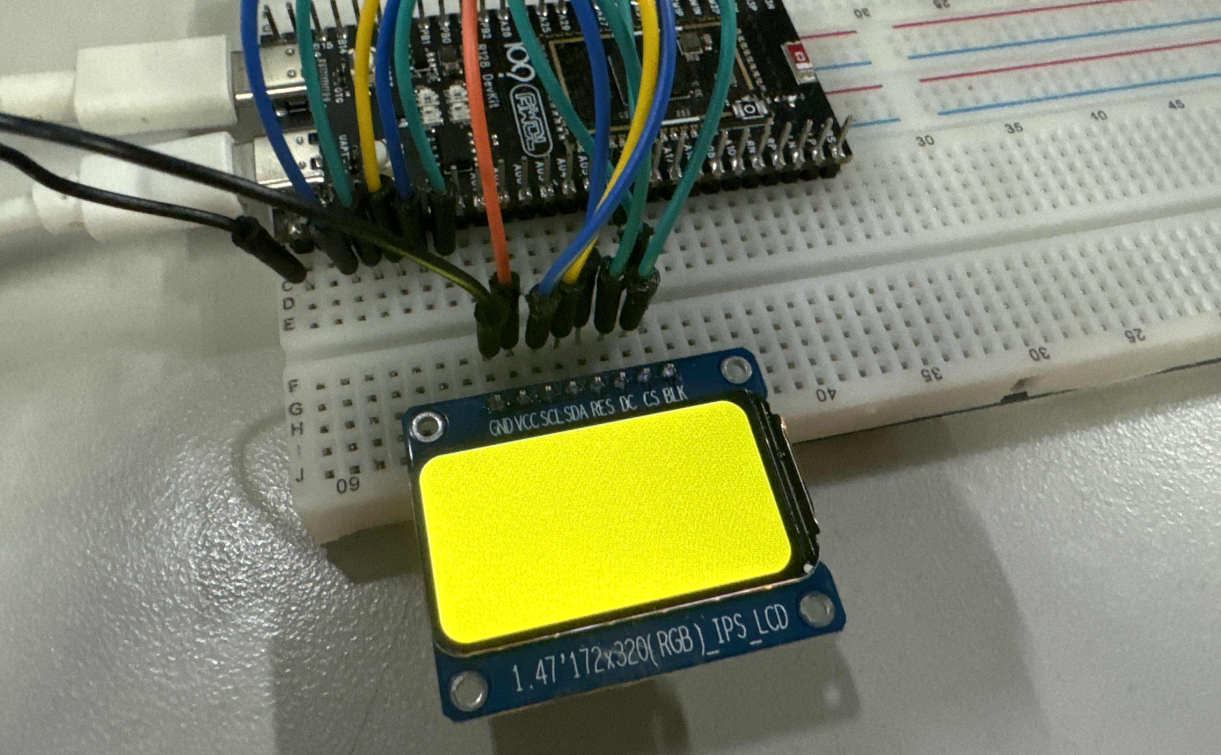

輸入 test_spilcd ,屏幕顯示黃色。

輸入 lv_examples 1 可以顯示 lvgl 界面

常見問題

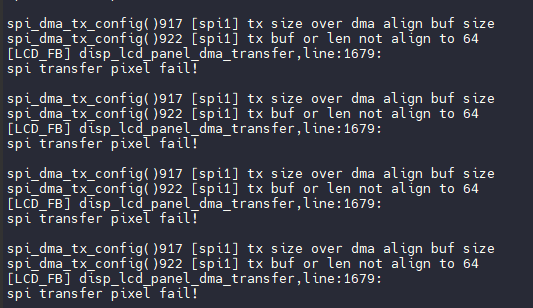

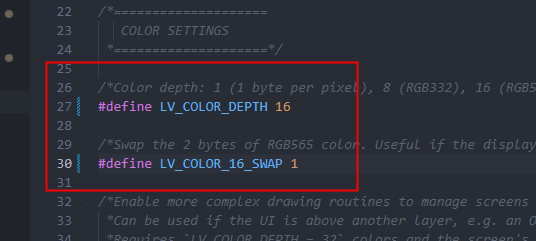

LVGL 出現 DMA OVER SIZE

這是由于 LVGL 配置的 LV_COLOR_DEPTH 為 32,但是 SPI 屏配置為16位。請修改 lv_conf.h

-

SPI接口

+關注

關注

0文章

258瀏覽量

34228 -

SDA

+關注

關注

0文章

123瀏覽量

27962 -

LCD顯示屏

+關注

關注

1文章

91瀏覽量

13188 -

TFT模塊

+關注

關注

0文章

4瀏覽量

6465 -

PWM驅動

+關注

關注

0文章

28瀏覽量

1166 -

R128

+關注

關注

0文章

41瀏覽量

76

發布評論請先 登錄

相關推薦

全志R128應用開發案例—適配SPI驅動ST7789V2.4寸LCD

全志R128應用開發案例—適配SPI驅動ST7789V2.4寸LCD

評論