Introduction to medical instruments and growing trend for point of care and near patient testing

This tutorial discusses the growing trend of using medical instruments in point-of-care and near-patient settings. Focusing on representative examples (blood gas analyzers and flow cytometers) from the analytical instrument segment, it describes critical design considerations for migrating these medical devices to portable form factors.

Overview

Medical instruments include analytical, audiology (except hearing aids), dental, ophthalmic, prosthetic, and surgical instruments. This section focuses on representative examples from the analytical instrument segment: blood gas analyzers and flow cytometers.

Analytical instruments are used in research and diagnostic applications for the medical and life sciences. Traditionally, these instruments have primarily been found in laboratory environments. Yet, as diagnostics continue to move from central laboratories to the point of care, analytical instruments are increasingly used in hospitals and other near-patient settings.

While this trend has increased the available market for analytical instruments, it has also placed new demands on system designers.

Size, power consumption, cost, and ease of use are critical considerations for enabling penetration into nontraditional markets. The instruments must be small enough to fit on benchtops. If portable, they need to be optimized for battery operation. Additionally, they should be inexpensive to enable purchase by point-of-care providers, and versatile to perform multiple tests for improved cost efficiency. Lastly, since operators may no longer be trained technicians, they need to be easy to use and intuitive.

Maxim serves this market with a broad portfolio of medical-grade solutions. The company's advanced process technologies bring new levels of precision, integration, and power savings to medical instrument designs.

Key benefits

- High-performance signal path solutions deliver accuracy that exceeds equipment requirements

- Sophisticated fuel-gauging algorithms pair with advanced power-management circuits to boost battery life in portable instruments

- Integrated supervisors provide multiple levels of self-monitoring for enhanced reliability

- Innovative touch-screen controllers enable more-intuitive user interfaces

- Broad variety of interface solutions supports multiple connectivity options

Blood gas analyzers

Overview

Commonly used for patient monitoring and diagnosis, blood gas analyzers quantify and analyze the amount of various gases within blood. They operate in a similar way to blood glucose monitors (see application note 4659, "Blood glucose meters"). A chemical reagent is mixed with a sample of blood, which is examined using either photooptical sensors or electrochemical sensors. The readings of the blood sample are compared against a calibration reagent to determine the result.

Applications

Blood gas analyzers are often used for simple blood tests, as well as for sophisticated suites of tests that allow physicians to monitor patient health in various settings. In addition to clinical diagnostics, blood gas analyzers are finding use in respiratory therapy and point-of-care diagnostics. These markets require device miniaturization and sophistication. Small, sometimes handheld, form factors are needed that integrate multiple testing capabilities, such as blood glucose and electrolyte analysis. This testing versatility increases the cost effectiveness of the device.

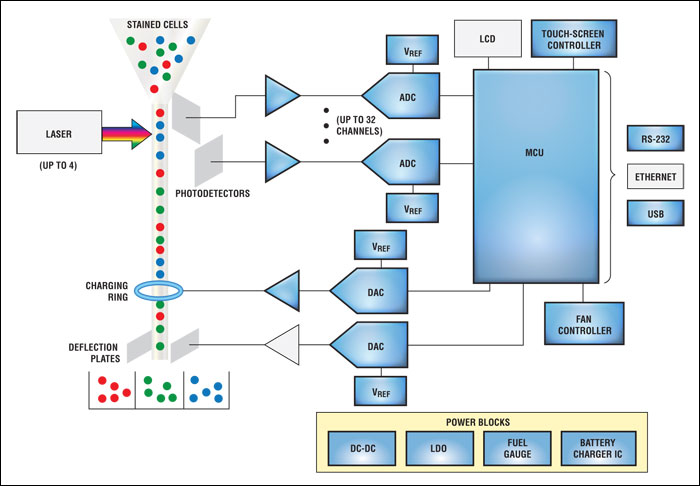

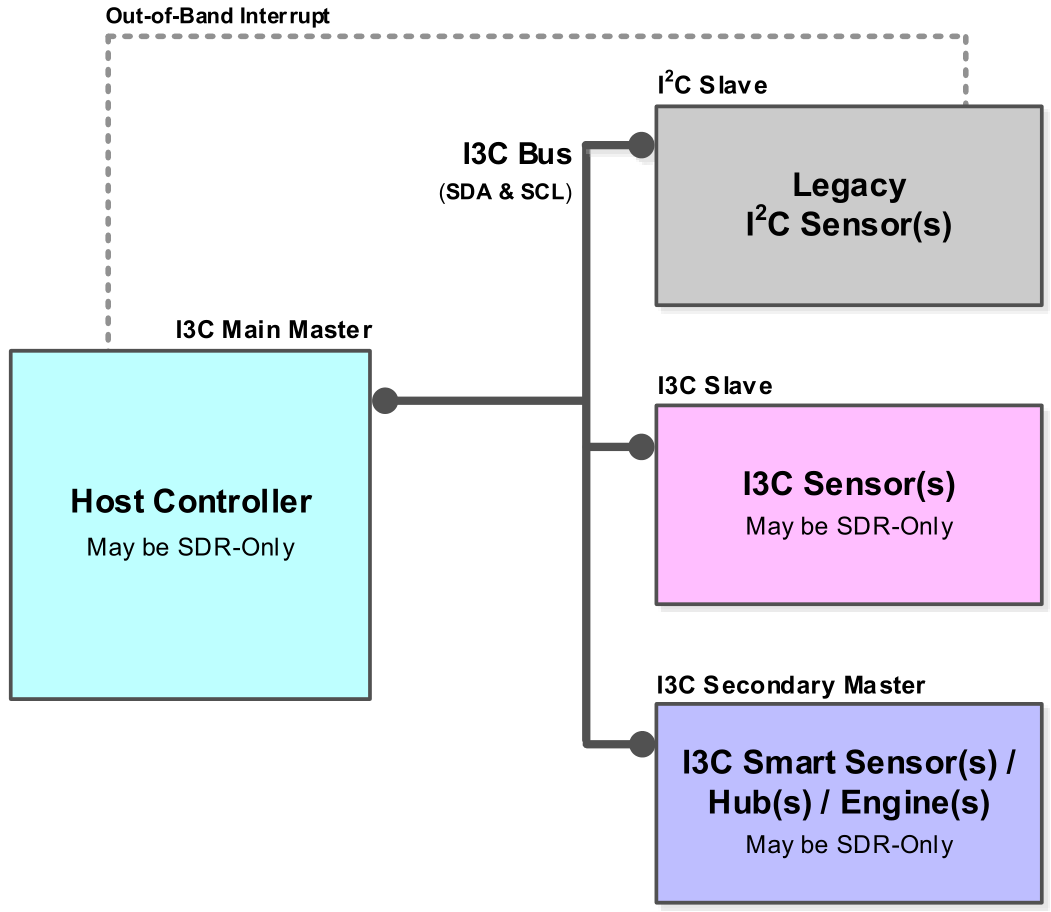

Signal path

Most blood gas analyzers have multiple sensors that are driven through an amplifier and a multiplexer to an analog-to-digital converter (ADC). The data is processed in the microcontroller, which is connected to a PC or other instruments through RS-232, USB, or Ethernet. A digital-to-analog converter (DAC) is often used to calibrate the sensor amplifiers to maximize the sensitivity of the electrodes.

Display

Modern blood gas analyzers increasingly employ a touch screen in combination with a graphical user interface (GUI) to make the programming process more intuitive. Visible, audible, and haptic responses to user inputs help designers improve the user experience. Advanced touch-screen controllers from Maxim offer haptic feedback, touch processing to reduce bus traffic, and autonomous modes for precision gesture recognition.

System block diagram for a blood gas analyzer. For a list of Maxim's recommended solutions for blood gas analyzers, go to www.maxim-ic.com/bga.

Flow cytometers

Overview

Flow cytometers were originally used to count blood cells. Today, they are relied upon to perform a variety of cell-based analyses in disciplines ranging from immunology to stem cell research.

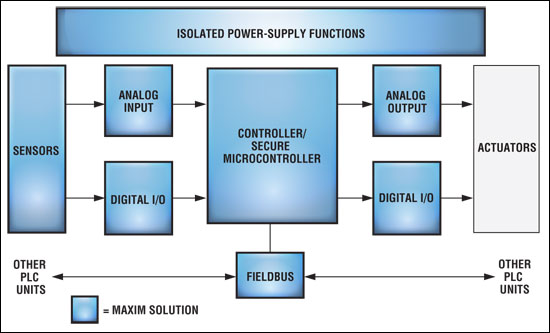

The cells to be counted are first stained with proteins that fluoresce in response to certain wavelengths of light. These proteins are designed to attach only to certain cells. In some cases, cells are not stained, as they have native proteins that fluoresce. The cells are forced down a tube whose pore size has been set to allow only a specific range of cell sizes to pass. These cells flow past one to four lasers with different wavelengths. When passing through the laser beam, the proteins will fluoresce at a longer wavelength than the lasers.

Photodetectors capture these wavelengths and measure the scattered light from the original source. The different wavelengths allow the instrument to determine the size and type of cell. The output of the photodetectors is amplified and used to drive the ADCs. Typically, there is one ADC per channel. All of the data is processed by a digital signal processor (DSP), and histograms are generated showing the types of cells counted.

Once the cells pass by the laser, they are charged by a charging ring. The amount of charge is determined by the type of cell. Deflection plates then sort the cells into different test tubes for further analysis.

Applications

Spurred by advancements in genomic and proteomic research, flow cytometers continue to expand their reach into new applications. Yet, in order to enable this broader use, they must be made more affordable. With normal price tags extending from $50,000 to $500,000, flow cytometers remain too expensive for many point-of-care diagnostic facilities and, even more so, for third-world markets, where they are needed for HIV/AIDS therapy.

Miniaturized, integrated point-of-care systems are required to meet the needs of emerging markets. These systems demand high throughputs to allow more samples to be processed, support for multiple colors to deliver extended testing functionality, and increased ease of use with automation capabilities.

System block diagram for a flow cytometer.

電子發(fā)燒友App

電子發(fā)燒友App

評論