Abstract: The DS1851 is a dual 8-bit digital-to-analog converter (DAC) which also contains dual independent 40-byte look-up tables (LUTs) and an internal digital temperature sensor. Its original application was the temperature compensation of bias circuits used in laser (VCSEL) drivers. This application brief describes how to use this A/D converter to provide the same type of temperature compensation in varactor diodes, variable capacitors commonly used in RF circuits.

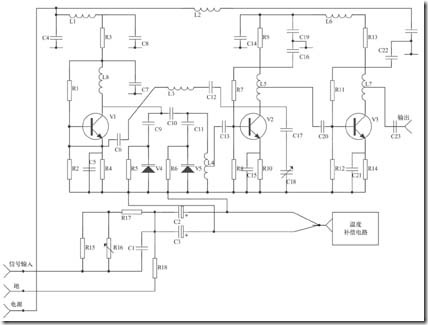

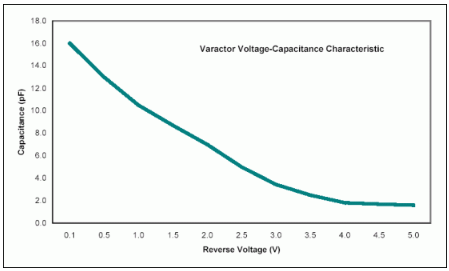

Figure 1. Typical varactor voltage-capacitance characteristic.

Being able to vary the capacitance with a control voltage is useful especially in radio frequency (RF) applications. Varactors can be used to tune systems for gain and phase alignment and they are also commonly used in voltage controlled oscillator (VCO) applications.

Varactors exhibit a large positive temperature coefficient. The temperature coefficient also varies with the applied reverse voltage. The temperature coefficient can vary between 100 PPM/°C [parts per million (PPM) per degree Celsius (C)] to over 1200 PPM/°C. See Figure 2 for a typical varactor capacitance temperature coefficient characteristic.

Figure 2. Typical varactor capacitance temperature coefficient characteristic.

In most closed applications, the large temperature coefficient that varactors exhibit is not of major concern but in open-loop systems where performance is critical, it may be necessary to adjust the reverse bias voltage to account for the capacitance drift over temperature. This application note describes how the DS1851 can be used to adjust the reverse bias voltage over temperature to maintain a constant varactor capacitance.

Figure 3 demonstrates how the DS1851 can be used to set the capacitance of varactor diodes and also compensate for the temperature coefficient. Since varactor diodes have a positive temperature coefficient and since the capacitance decreases with increasing reverse bias, the LUT in the DS1851 needs to be programmed with increasing values for higher temperatures and decreasing values for lower temperatures.

Each DAC adjacent step in the DS1851 corresponds to a 3906 PPM step either up or down. The DAC step rate to match the varactor temperature coefficient can be calculated from the following formula:

Figure 3. DS1851 varactor temperature compensation circuit.

Notes:

Varactor Characteristics

Varactors are diodes that exhibit large changes in capacitance when the reverse bias is varied. The capacitance of a varactor decreases as the reverse bias is increased. A capacitance change ratio of greater than 5 is not uncommon. See Figure 1 for a typical varactor voltage-capacitance characteristic.

Figure 1. Typical varactor voltage-capacitance characteristic.

Being able to vary the capacitance with a control voltage is useful especially in radio frequency (RF) applications. Varactors can be used to tune systems for gain and phase alignment and they are also commonly used in voltage controlled oscillator (VCO) applications.

Varactors exhibit a large positive temperature coefficient. The temperature coefficient also varies with the applied reverse voltage. The temperature coefficient can vary between 100 PPM/°C [parts per million (PPM) per degree Celsius (C)] to over 1200 PPM/°C. See Figure 2 for a typical varactor capacitance temperature coefficient characteristic.

Figure 2. Typical varactor capacitance temperature coefficient characteristic.

In most closed applications, the large temperature coefficient that varactors exhibit is not of major concern but in open-loop systems where performance is critical, it may be necessary to adjust the reverse bias voltage to account for the capacitance drift over temperature. This application note describes how the DS1851 can be used to adjust the reverse bias voltage over temperature to maintain a constant varactor capacitance.

Using DS1851 to Compensate for Varactor Capacitance Drift with Temperature

The DS1851 is a dual 8-bit digital-to-analog converter (DAC) which also contains dual independent 40-byte lookup tables (LUT) and an internal digital temperature sensor. The temperature sensor points to each location in the LUT in 4°C increments over the temperature range from -40°C to +95°C. In this manner, the LUT can assign a unique value to each DAC at any temperature to match a particular temperature coefficient.Figure 3 demonstrates how the DS1851 can be used to set the capacitance of varactor diodes and also compensate for the temperature coefficient. Since varactor diodes have a positive temperature coefficient and since the capacitance decreases with increasing reverse bias, the LUT in the DS1851 needs to be programmed with increasing values for higher temperatures and decreasing values for lower temperatures.

Each DAC adjacent step in the DS1851 corresponds to a 3906 PPM step either up or down. The DAC step rate to match the varactor temperature coefficient can be calculated from the following formula:

DAC Step Rate = 3906 PPM / [4°C x Varactor Temperature Coefficient (PPM/°C)]As an example, if for a particular reverse bias setting the varactor has a 600 PPM/°C temperature coefficient, then the LUT needs to be programmed to increase and decrease the DAC steps about every 1.63 positions to match the varactor temperature coefficient. This could be implemented by programming 5 increasing/decreasing values over an 8-byte range (8 bytes / 5 bytes = 1.6).

Figure 3. DS1851 varactor temperature compensation circuit.

Notes:

- The maximum recommended capacitive load for the DS1851 is 1000pF.

- The maximum output current drive for the DS1851 is 150μA.

電子發燒友App

電子發燒友App

評論